A conical rod is a structural element that tapers from one end to the other, creating a cone-like shape. Unlike a uniform cylindrical rod, a conical rod gradually decreases or increases in diameter along its length, making it an essential tool in engineering, architecture, mechanics, and industrial applications. This unique form allows it to distribute stress differently compared to straight rods, improving efficiency and functionality in many practical uses. Whether in construction, testing, or industrial design, the conical rod serves as a versatile component with measurable advantages. Understanding its properties, types, applications, and relevance in modern industries is vital for engineers, students, and professionals.

The significance of a conical rod lies not only in its geometry but also in the way it interacts with external forces. Its tapering shape often reduces material consumption while maintaining structural integrity, making it both economical and durable. Additionally, conical rods are used in scientific experiments to study mechanical vibrations, elasticity, and torsional properties. They are also found in industries like aerospace, automobile manufacturing, and civil engineering, where precise load distribution is crucial. This article explores every aspect of conical rods, from their fundamental principles to practical uses, while answering common questions about their role in modern innovation. By the end, readers will gain a comprehensive understanding of why this simple yet effective design has remained relevant for centuries.

What is a Conical Rod?

A conical rod is a rod whose diameter varies uniformly along its length. One end of the rod is thicker, while the other end is thinner, creating a conical geometry. This design alters the way stress, strain, and vibrations travel through the material. Engineers often prefer conical rods when load distribution must be gradual rather than abrupt. The reduction or increase in cross-sectional area influences stiffness, resistance, and resonance, allowing controlled performance under specific conditions.

Conical rods are not limited to one type of material. They can be manufactured from steel, aluminum, wood, plastic, or composites depending on the industry requirements. For instance, in laboratories, conical rods are used in elasticity experiments, while in structural applications, they may be part of towers, bridges, or poles. The design ensures mechanical advantage by balancing weight and strength.

Geometrical Properties of a Conical Rod

The geometry of a conical rod directly influences its behavior under stress and load. Its tapering shape leads to variable cross-sectional area, which must be carefully calculated in engineering applications.

| Property | Description |

|---|---|

| Shape | Tapered rod, gradually reducing or increasing diameter |

| Cross-sectional area | Varies along the length, usually circular |

| Length (L) | Distance between thicker end and thinner end |

| Diameter variation | Linear change from maximum diameter (D1) to minimum diameter (D2) |

| Moment of inertia | Changes along the rod due to variable radius |

| Load distribution | More gradual compared to uniform cylindrical rods |

| Stress concentration | Reduced in areas where geometry disperses force |

These properties make conical rods advantageous where gradual energy transfer or weight reduction is required. Engineers calculate dimensions using taper ratios to ensure the rod withstands specific stresses without failure.

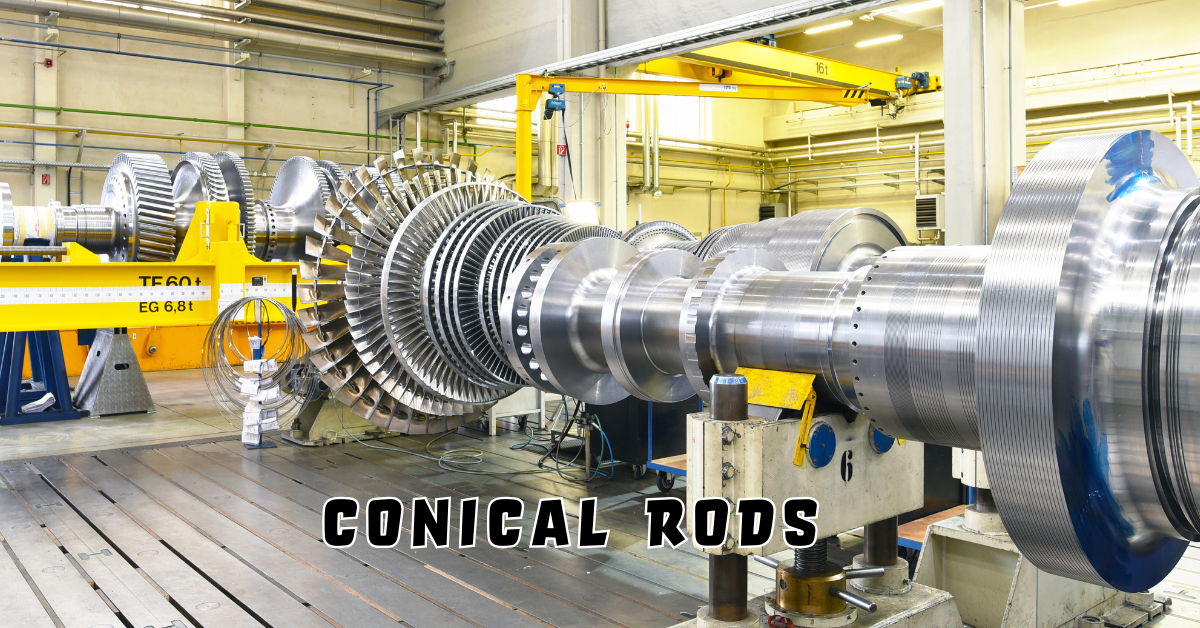

Applications of Conical Rods

Conical rods are used across multiple industries due to their adaptability and strength. Their tapering shape provides a variety of applications that cylindrical rods may not achieve efficiently.

Engineering and Construction

In civil engineering, conical rods are often used in poles, towers, and suspension systems. The taper allows them to carry varying loads without sudden stress points, enhancing safety.

Mechanical Testing

Laboratories use conical rods for studying stress, strain, and vibrations. Their shape provides varying cross-sections, making them ideal for elasticity experiments and wave propagation studies.

Aerospace and Automotive Industries

Aircraft wings, suspension rods, and automotive shafts often integrate conical rod designs for better stress distribution, lightweight performance, and durability.

Architectural Elements

Conical rods are also part of aesthetic and functional designs in architecture, such as tapered columns or artistic structural rods.

Energy Transmission

In wind turbines, power poles, and antenna supports, conical rods are used to reduce material costs while improving stability.

Advantages of Conical Rods

The uniqueness of conical rods lies in their mechanical and economical advantages.

| Advantage | Explanation |

|---|---|

| Weight efficiency | Reduces material consumption without sacrificing strength |

| Stress distribution | Gradual variation prevents sudden failures |

| Vibrational properties | Useful for experiments involving mechanical waves |

| Aesthetic design | Preferred in architecture for sleek appearance |

| Load adaptability | Can handle different loads across length |

| Reduced fatigue | Less prone to cracks due to even force transfer |

These benefits explain why industries often adopt conical rods instead of uniform cylindrical rods when specific conditions demand improved efficiency.

Manufacturing of Conical Rods

Manufacturing a conical rod requires precision to achieve the tapering dimensions. Depending on the material, different techniques are employed.

- Casting – Molten metal is poured into a conical mold, solidifying into a rod.

- Machining – Cylindrical rods are tapered using lathes or CNC machines.

- Extrusion – Metals or polymers are forced through conical dies to form tapered rods.

- Forging – Heated metals are hammered or pressed into a conical shape.

- Composite Forming – For lightweight rods, fibers are laid in tapered molds and bound with resin.

Each method is chosen based on the required strength, finish, and cost-effectiveness. For example, aerospace industries often rely on machining for precision, while construction uses casting for bulk production.

Conical Rod in Mechanical Vibrations

One of the most fascinating applications of conical rods lies in the study of vibrations and elasticity. When subjected to stress or oscillations, conical rods show unique wave propagation due to their variable cross-sectional area. This makes them crucial in experimental mechanics, where engineers study wave velocity, natural frequencies, and damping behavior.

Researchers often use conical rods in educational settings to teach students about elasticity, bending moments, and torsion. Because of their changing diameter, they reveal more complex results compared to cylindrical rods, offering deeper insights into real-world applications.

Conical Rod vs Cylindrical Rod

It is essential to distinguish conical rods from cylindrical rods to understand their respective applications.

| Feature | Conical Rod | Cylindrical Rod |

|---|---|---|

| Shape | Tapered, varying diameter | Uniform diameter along entire length |

| Stress distribution | Gradual and even | Concentrated at points |

| Material consumption | Less due to taper | More due to uniform thickness |

| Applications | Towers, aerospace, testing | Shafts, beams, general structures |

| Vibrational response | Complex, varied wave propagation | Simpler response |

This comparison shows that while cylindrical rods are more common, conical rods are chosen for specific tasks where weight reduction and stress distribution are more critical.

Challenges in Using Conical Rods

Despite their advantages, conical rods present some challenges. Their geometry complicates calculations for stress, strain, and deflection. Engineers must rely on advanced formulas or computational tools to analyze them accurately. Manufacturing precision is also more demanding compared to cylindrical rods, often raising costs. Moreover, in large-scale applications, alignment and fitting issues may arise because of their taper. These challenges, however, are usually outweighed by their performance benefits.

Future Potential of Conical Rods

With the increasing demand for lightweight and sustainable designs, conical rods are likely to see expanded use in industries. Innovations in composite materials and 3D printing may reduce manufacturing challenges, making them more accessible. In renewable energy systems like wind turbines and solar structures, conical rods could play a key role in enhancing strength while lowering material usage. The architectural sector is also expected to adopt them more widely for modern, aesthetically pleasing designs that maintain durability.

FAQs on Conical Rods

1. What is the main purpose of a conical rod?

The primary purpose is to provide gradual stress distribution, reducing failure risks and optimizing material usage in engineering.

2. Why are conical rods used in vibration experiments?

They display unique wave propagation due to their varying cross-section, making them ideal for studying elasticity and vibrations.

3. What materials are commonly used to manufacture conical rods?

Steel, aluminum, composites, and even wood, depending on application requirements like strength, weight, and durability.

4. How do conical rods differ from cylindrical rods?

Cylindrical rods have uniform diameter, while conical rods taper, leading to improved weight efficiency and stress management.

5. Are conical rods cost-effective?

Yes, especially in large structures where reduced material usage translates into cost savings without compromising strength.

Conclusion

The conical rod represents a balance of geometry, strength, and efficiency. From laboratories to skyscrapers, its role spans diverse fields where tapering is not just an aesthetic choice but a structural necessity. Its unique ability to manage stress distribution, reduce weight, and provide enhanced vibrational properties makes it superior in many engineering applications. Challenges such as complex calculations and manufacturing costs exist, but modern technologies are addressing these issues, ensuring broader adoption in the future.

As one engineer famously said, “Design is intelligence made visible, and geometry is the language of strength.” The conical rod exemplifies this principle by showing how a simple change in form can unlock powerful advantages. Another expert described it as “a silent hero in engineering,” emphasizing its understated yet crucial role. Looking forward, as industries evolve toward sustainability and efficiency, the conical rod is poised to remain an indispensable tool—shaping not only structures but also the future of design.